Condition monitoring

What is Condition Monitoring?

Condition monitoring programs allow teams to move from reactive to predictive maintenance. Aggregating around-the-clock measurements provides teams with a clear picture of asset health and performance without expending labor. A condition monitoring program can also:

- Decrease maintenance costs

- Improve downtime response

- Move teams to condition-based maintenance

- Save costs on prematurely changed resources

How to get the most value from condition monitoring

Condition monitoring strengthens your maintenance and reliability program by:

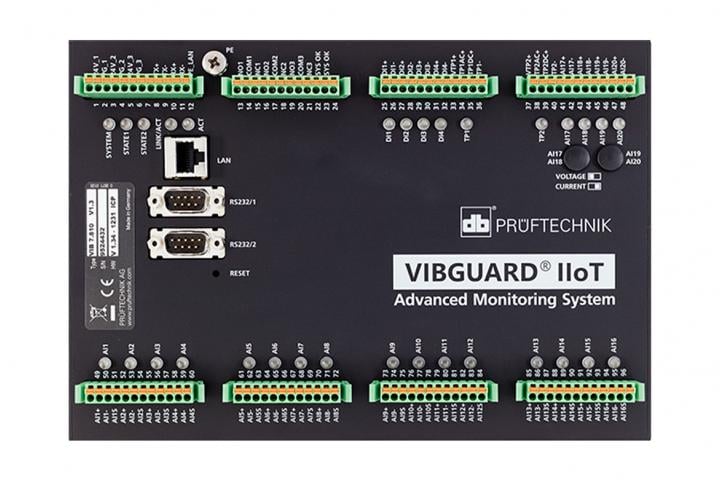

Gain continuous, always-on monitoring of assets

When internet-enabled devices are connected to software, real-time measurements are automatically aggregated around the clock. Data is stored in the cloud where it is assigned to assets and organized for users to review.

Identify the root cause faster

Teams can swiftly troubleshoot assets using different condition monitoring devices, such as vibration sensors or power monitors. Compare measurements over time to quickly pinpoint abnormalities.

Monitor equipment safely from anywhere

Connect your people and assets with remote sensors and mobile access. Measurements from wireless sensors are automatically sent to the cloud without human intervention or error. Teams can access data remotely from smart devices anywhere there’s an internet connection.

eMaint CMMS

Fluke Connect

Connect2Assets

Fluke Mobile

Connected reliability

Power monitoring

Vibration

eMaint Condition Monitoring

Monitor asset health and see machine failures coming with eMaint condition monitoring.

5 Steps to condition monitoring

Head to the Fluke.com Blog to learn about how to quickly add CM sensors to assets.

Learn about CBM best practices

Get a better grasp of Condition Monitoring from this expert-led webinar on Accelix.com.