Multifunction calibrator tools

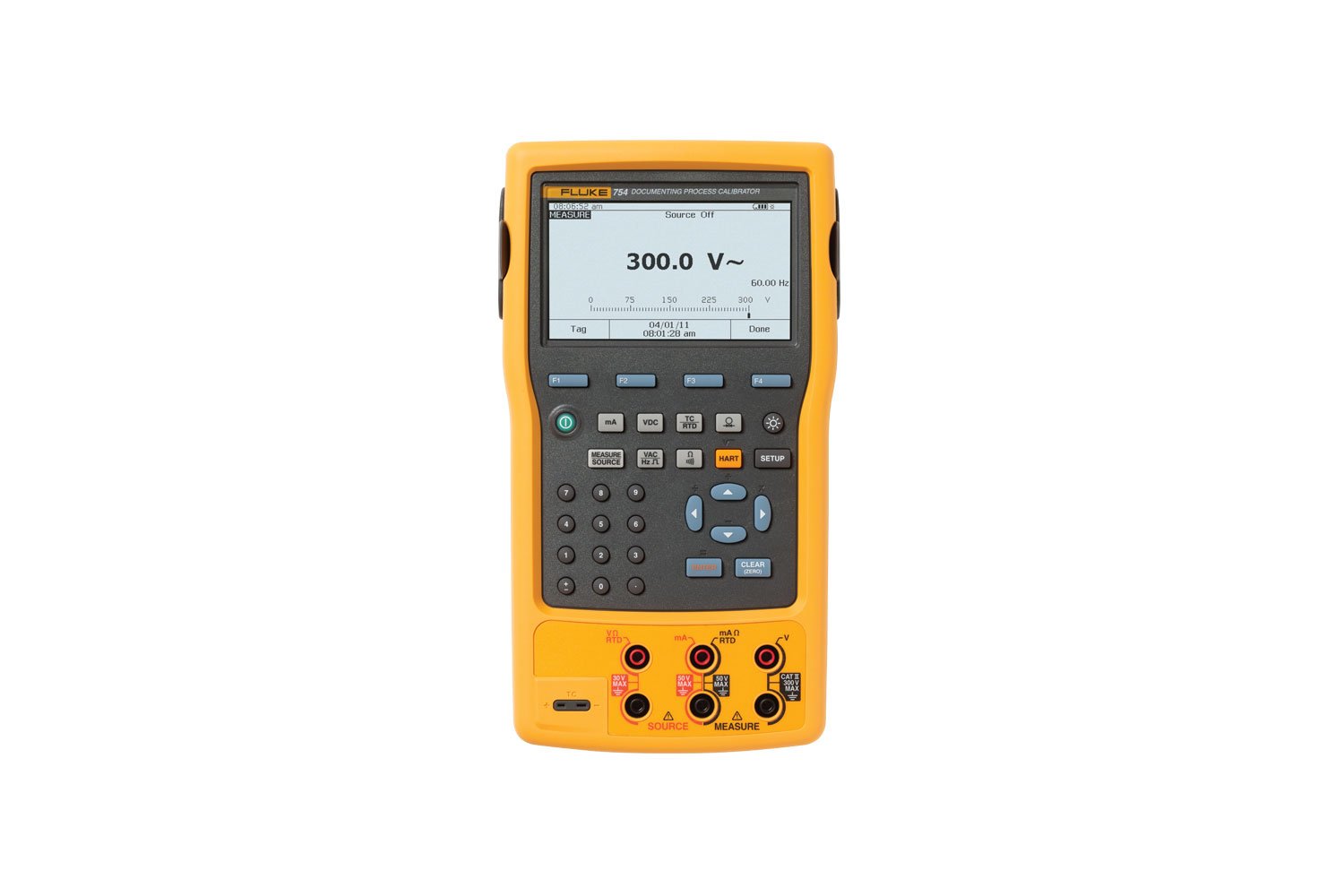

Fluke Multifunction Calibrator Process Tools are designed to calibrate almost anything. These calibrators source, measure and simulate almost all process parameters, and documenting versions even document the results. The Fluke 754 does the work of several tools - sourcing, simulating and measuring pressure, temperature, and electrical signals in one compact, hand-held device. The Fluke 726, specifically designed for process industries, measures and sources almost all process parameters and can calibrate almost anything in the plant.

Fluke Multifunction Calibrator Process Tools are designed to calibrate almost anything. These calibrators source, measure and simulate almost all process parameters, and documenting versions even document the results. The Fluke 754 does the work of several tools - sourcing, simulating and measuring pressure, temperature, and electrical signals in one compact, hand-held device. The Fluke 726, specifically designed for process industries, measures and sources almost all process parameters and can calibrate almost anything in the plant.

Find the right pressure calibrator

Find the right pressure calibrator

Multifunction calibrator solutions

There is no one size fits all calibrator that meets the requirements of all users.

Our process calibration tools product selector can help you choose the right process calibrator for the task you need to perform.

Best value

Best overall

For experts

Fluke 753 Documenting Process Calibrator

The 753 does the work of several tools – sourcing, simulating and measuring pressure, temperature,...

Fluke 154 HART Communicator

The Fluke 154 is a standalone tablet based HART® communication tool. The tablet configured with the...

Fluke 726 Precision Multifunction Calibrators

Calibrate thermocouples and RTD temperature instruments

Fluke 700PCK Pressure Calibration Kit

The Fluke 700PCK makes it possible to calibrate your pressure modules at your facility using your...

Fluke TL80A Basic Electronic Test Lead Kit

Test leads are an integral part of the complete measurement system and extend the capabilities of...