Supervisión de estado

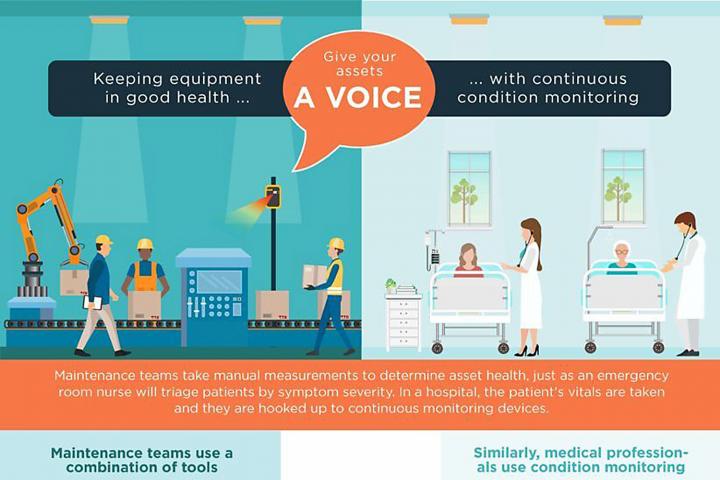

Condition monitoring programs allow teams to move from reactive to predictive maintenance. Aggregating around-the-clock measurements provides teams with a clear picture of asset health and performance without expending labor. A condition monitoring progam can also:

- Decrease maintenance costs

- Improve downtime response

- Move teams to condition-based maintenance

- Save costs on prematurely changed resources

Cómo aprovechar al máximo la supervisión del estado

La supervisión del estado refuerza su programa de mantenimiento y fiabilidad del siguiente modo:

Obtenga una supervisión continua y permanente de los activos.

Cuando los instrumentos o sensores están conectados al software, las medidas en tiempo real se agregan automáticamente las 24 horas del día. Los datos se almacenan en la nube donde se asignan a los activos y se organizan para que los usuarios puedan revisarlos.

Identifique más rápidamente el origen del problema

Solucione rápidamente los problemas de los activos utilizando diversos equipos de supervisión del estado, como sensores de vibración o equipos de supervisión eléctrica. Compare las medidas a lo largo del tiempo para identificar rápidamente las anomalías.

Supervise los equipos de forma segura desde cualquier lugar

Conecte a sus colaboradores y a sus activos con sensores remotos y acceso móvil. Las medidas de los sensores inalámbricos se envían automáticamente a la nube sin intervención humana ni errores. Los operarios pueden acceder a los datos de forma remota desde dispositivos inteligentes en cualquier lugar donde haya una conexión a Internet.

Monitoreo de la Potencia Eléctrica

Vibración

Visualize condition monitoring

Maintenance managers can use condition monitoring to visualize health problems in equipment.

5 Steps to condition monitoring

Head to the Fluke.com Blog to learn about how to quickly add CM sensors to assets.